Construction Safety Best Practices: How General Contractors Protect Workers and Projects

Construction is consistently one of the most hazardous industries in the United States. Workers face risks ranging from falling from heights and being struck by equipment to electrocution, trench collapse, scaffold failure, repetitive motion injuries, and exposure to silica or asbestos.

For general contractors, prioritizing worker safety is essential—not just for compliance, but also for protecting project timelines, maintaining workforce morale, and safeguarding your company’s reputation.

Table of Contents

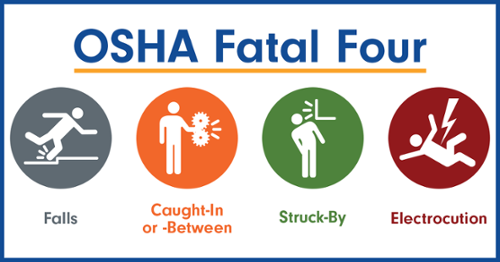

The Fatal Four: Construction’s Leading Hazards

In 2023, construction fatalities remained high, with nearly 1 in 5 workplace deaths occurring in the industry. The “Fatal Four” account for the majority of these deaths:

-

Falls

-

Struck by Object

-

Electrocutions

-

Caught-in/between

OSHA estimates that eliminating these hazards could save over 600 lives each year. Addressing these risks proactively should be a top priority for general contractors managing commercial construction sites.

Most Common OSHA Violations in Construction

Regularly reviewing OSHA’s most cited violations helps contractors focus on high-risk areas. In recent years, frequent violations have included:

-

Fall protection (construction)

-

Hazard communication (general industry)

-

Scaffolding safety (construction)

-

Respiratory protection (general industry)

-

Control of hazardous energy (lockout/tagout)

-

Ladder safety (construction)

-

Powered industrial trucks (general industry)

-

Fall protection training

-

Machinery and machine guarding

-

Eye and face protection

Focusing on these areas not only reduces the risk of accidents but also helps contractors avoid costly OSHA fines.

Implementing a Comprehensive Construction Safety Program

A proactive safety program is the backbone of any successful commercial construction project. Key steps include:

- Develop a formal safety and health program – Create clear procedures and expectations for employees, making safety a company-wide priority.

- Provide ongoing training – Regular safety training ensures workers know how to identify and prevent hazards.

- Conduct frequent inspections – Check job sites, equipment, and materials regularly to spot potential dangers before they become incidents.

- Maintain accurate records – Document injuries and illnesses to comply with OSHA and monitor trends in workplace safety.

- Report fatalities and severe injuries – Ensure all serious incidents are reported according to OSHA standards.

- Provide access to exposure and medical records – Transparency builds trust with employees and ensures regulatory compliance.

Companies that implement robust safety programs may also qualify for focused OSHA inspections, which are narrower and less disruptive than full-site inspections.

Why Safety Programs Are a Smart Business Strategy

Investing in construction safety goes beyond compliance. Benefits include:

-

Minimized project delays due to accidents or injuries

-

Higher employee morale and retention

-

Enhanced company reputation with clients and partners

-

Improved project quality and efficiency

-

Cost savings by preventing workplace incidents

By identifying and addressing hazards before they occur, general contractors strengthen communication, trust, and overall project success. Safety programs also reinforce the message that employee well-being is a priority, which can boost productivity and profitability.

Essential Resources for Construction Safety

General contractors can rely on these OSHA resources to build and maintain effective safety programs:

Leveraging these guides ensures your company stays up to date with safety standards while protecting both workers and projects.

Why Arizona Businesses Trust Emerald Inc.

For over 20 years, Emerald Inc. has delivered high-quality tenant improvements, office remodels, medical and dental build-outs, and retail construction projects across Arizona. Our design-build method is built on:

-

Transparent communication

-

Commitment to budget and timelines

-

Accurate cost forecasting

-

Experienced project leadership

-

Extensive subcontractor relationships

-

Strong understanding of Arizona permitting and construction requirements

Whether you’re upgrading a corporate office, modernizing a clinic, expanding your dental practice, or building out a new retail space, design-build gives you the most efficient, predictable, and successful path to a completed project.

Just a few of the fantastic clients in Arizona Emerald Inc. has worked with

Ready to Start Your Arizona Build-Out or Remodel?

Let’s talk about your project.

Whether you’re exploring budgets, design options, or a full remodel, our team will guide you through the process and deliver a tailored, accurate plan for your space.

Contact Emerald Inc. today to start planning your next project.

📞 Call us at 480-832-9808

📧 Email us to schedule a free consultation

👉 Let’s design a space that keeps customers coming back.